Product

Optimized & Industry-ready Solutions

Products

HK Hantie Group Limited offers a diverse range of products designed to meet a wide variety of customer needs, including custom products and OEM services. With a wealth of production techniques and flexibility, HK HANTIE is dedicated to providing customers with clad metal plates, laminated sheets featuring various patterns and film materials, as well as deep processing of steel coils for different industrial applications.

In addition to our own products, we also offer OEM/ODM services. Our production lines are designed to meet customer specifications and technical requirements, providing significant convenience. Our clad metal plates segment includes various composite metal sheets and bars. The VCM and Film Coated Glass panels feature a range of PVC and PET polymer films, as well as patterns and textures with metallic, natural, or other customer-specific designs. Our steel processing and distribution services include slitting, leveling, and other deep processing of raw materials such as steel plates (coils), stainless steel, titanium plates, aluminum plates, copper plates, nickel-based alloys, INCOLOY alloys, Hastelloy alloys, and other alloy plates, as well as electrical steel.

We look forward to becoming your ideal partner by providing products of the highest quality.

Our Advantages

- 3rd Party Certification: We offer free sample services to our customers. To ensure that the delivered goods meet contract requirements, we can arrange inspections by third-party certification bodies and provide testing reports on dimensions, mechanical properties, chemical composition, iron loss, antibacterial, or fire-resistant performance. These organizations include, but are not limited to: BV, SGS, INTERTEK, etc.

- Reputable Raw Materials: Our company has a stringent raw material procurement control system to ensure that all stainless steel, titanium plates, nickel-based alloys, and other raw materials are sourced from reputable factories. This guarantees that the raw materials have excellent mechanical properties and stable chemical compositions, meeting requirements for heat resistance, low-temperature resistance, acid resistance, or wear resistance. The PET and PVC films used in our laminated sheets are produced in-house, ensuring consistency in patterns, colors, and adhesion strength.

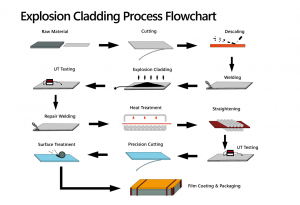

- OEM/ODM Service: Based on customers’ personalized needs, we achieve metallurgical bonding of two or more metals, such as titanium, zirconium, tantalum, silver, copper, aluminum, nickel-based alloys, stainless steel, and steel, through explosive cladding or roll bonding techniques. This enhances the overall physical, chemical, and mechanical properties while preserving the individual benefits of the clad and base metals, and reduces the use of rare and precious metals compared to using pure materials. We also offer customized solutions, including clad bars and laminated sheets with different patterns and colors, providing our customers with a broader range of options.

Clad Plates

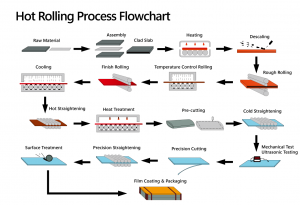

Clad metal plates can be produced by metallurgically bonding two or more metals, such as titanium, zirconium, tantalum, silver, copper, aluminum, nickel-based alloys, stainless steel, and steel, through explosive cladding or roll bonding techniques, according to customer requirements. These can be processed into plates, bars, or tubes. This material enhances the overall physical, chemical, and mechanical properties while retaining the excellent characteristics of both the cladding and base metals. Additionally, it reduces the use of rare and precious metals compared to pure materials, effectively lowering manufacturing costs in downstream industries.

VCM Laminated Metal Sheets

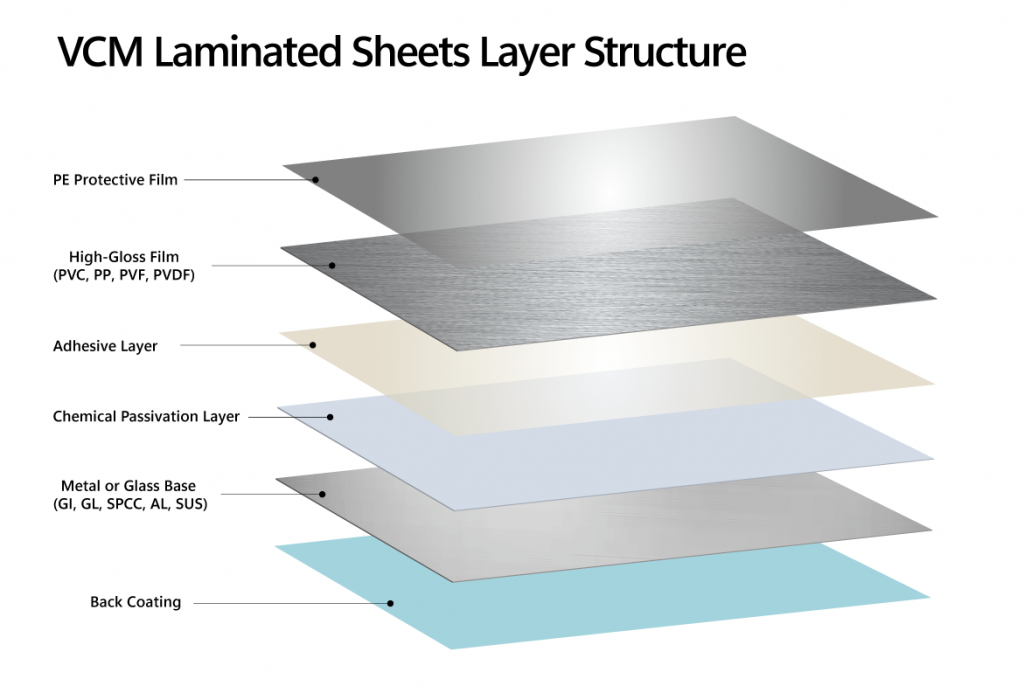

Laminated sheets refer to color-coated laminated steel sheets or tempered glass, which involve laminating one or more layers of polymer films, such as PVC or PET, onto the surface of steel plates or glass. These sheets retain the excellent strength and processability of metal or glass materials while also benefiting from the superior decorative, corrosion-resistant, weather-resistant, and pollution-resistant properties of polymer films. With the addition of an optional fire-resistant core layer, the product’s fire resistance can reach Class A standards. The combination of different colors and texture patterns, such as wood grain, floral patterns, fabric textures, stone textures, embossed patterns, and stainless steel metallic textures, provides a rich variety of appearances. These products can be applied in home appliance panels, interior or door panels, elevator decorations, automotive and ship interior decorations, and building exterior walls.

Metal Material Storage, Logistics, and Processing

We has established a robust system for the storage, logistics, and processing of metal materials, dedicated to delivering high-quality, diverse metal products and customized processing services through an all-in-one solution. The core materials are titanium products, stainless steel and duplex steel sheets and coils, nickel-based alloy sheets, structural & pressure vessel steel, pipeline steel, galvanized and aluzinc coils and specialty steels (9% nickel steel, wear-resistant steel, and electrical steel etc), leveraging our advanced storage, logistics, and processing capabilities, we offer tailored solutions including material cutting, slitting, and surface treatments to ensure materials meet exact specifications. Focused on customer satisfaction, we deliver responsive services and dependable supply chain management.

Our Innovations

Industry Focused Products!

Titanium-Steel Clad Plates

Titanium-steel clad plates significantly reduce product costs (approximately 50%-70% savings). These plates are widely used in industries such as electrolysis electrodes, condensers, hydrogen storage materials, petroleum refining, and seawater desalination heaters. For example, they are used in power plant chimney linings with TA2+Q235B.

Nickel-Based Alloy Clad Plates

Nickel-based alloy clad plates combine the surface properties of nickel alloys with the strength and toughness of base materials through processes like explosive welding and hot rolling. These plates are ideal for environments requiring high temperatures and corrosion resistance, such as petrochemical equipment, seawater desalination plants, and pressure vessels. For instance, X65MS+N06625 is suitable for acidic environments.

Duplex Steel Clad Plates

Duplex steel clad plates are used in applications such as petroleum pipelines, chemical storage tanks, heat exchangers, and marine structures. These plates offer an economical and durable solution for harsh environments. An example application includes marine methanol fuel tanks using CCS 2205+AH36.

VCM Laminated Plates

VCM Laminated Plates (Vinyl Laminated Steel Sheets) feature a high polymer film laminated onto the steel surface. These plates offer corrosion resistance, scratch resistance, and fire resistance, with an appealing aesthetic. They can be customized with various effects, ranging from low to high gloss and matte to pearlescent finishes.

Silicon Steel Sheets

Cold-rolled non-oriented silicon steel sheets are widely used in the manufacture of motors, transformers, generators, and electrical equipment cores due to their excellent magnetic properties and durability. A typical grade is 50W1300.

PVDF Laminated Plates

PVDF Laminated Plates are a type of VCM plate, where DuPont PVDF film is laminated onto a galvanized or galvalume base. These plates offer high weather and corrosion resistance, making them ideal for roofing and wall applications in construction projects.

Need Help with Easier Industrial Solutions? We Are Experts!

Contact