Titanium plates & bars

We supply titanium and titanium alloy materials, including TA1, TA2, TA10, TC4, and more, covering titanium plates, bars, processed parts, and forgings.

| Property | Specification |

|---|---|

| Thickness Range | 0.1mm – 3.0mm (coil); 0.3 – 120mm (plate) |

| Width | 300 – 3600mm |

Introduction

Titanium and titanium alloys are known for their exceptional strength, corrosion resistance, and lightweight properties, making them widely used in chemical processing, aerospace, medical devices, shipbuilding, and industrial manufacturing. We also offer customized processing services to meet specific customer requirements.

Production Process

- Smelting – Raw materials are refined into high-purity titanium ingots through vacuum arc remelting (VAR) or electron beam melting (EB).

- Forging and Rolling – Titanium ingots are processed into plates, bars, or forgings through forging, hot rolling, or cold rolling.

- Machining and Customization – Further processing to meet specific customer requirements for precision parts and forged components.

- Quality Control – Advanced non-destructive testing (e.g., ultrasonic testing) and chemical composition analysis ensure high purity and mechanical properties that meet international standards.

Classification

- By Material Type:

- TA Series (Pure Titanium): Includes TA1, TA2, and TA10, known for excellent corrosion resistance, ideal for harsh environments.

- TC Series (Titanium Alloys): TC4 (Ti-6Al-4V) is a typical titanium alloy offering a balance of high strength and corrosion resistance.

- By Product Form:

- Titanium Plates – Available in thin and medium-thick plates.

- Titanium Bars – Available in round, square, and hexagonal bars.

- Titanium Processed Parts – Custom parts and components.

- Titanium Forgings – High-performance forgings such as flanges, rings, and shafts.

Main Titanium and Titanium Alloy Grades and Standards

| Grade | China (GB/T) | USA (ASTM/UNS) | Europe (EN) |

|---|---|---|---|

| TA1 | GB/T 3621, GB/T 2965 | Grade 1 (UNS R50250) | 3.7025 |

| TA2 | GB/T 3621, GB/T 2965 | Grade 2 (UNS R50400) | 3.7035 |

| TA10 | GB/T 3621 | – | 3.7105 |

| TC4 | GB/T 3621, GB/T 2965 | Grade 5 (UNS R56400) | 3.7165 |

Standards:

GB/T 3621, GB/T 2965, GB/T 13810, GB/T 16598; ASTM B265, B348, B381; EN 10204.

Advantages and Disadvantages

- Advantages:

- Lightweight – Density is approximately 57% of steel, ideal for weight reduction applications.

- High Strength – Excellent strength-to-weight ratio, suitable for high-performance components.

- Corrosion Resistance – Outstanding resistance to seawater and chemical environments.

- Biocompatibility – Widely used for implants and medical devices.

- Disadvantages:

- High Cost – Complex production process leads to higher costs.

- Processing Challenges – High machining difficulty due to material properties.

Applications

- TA1、TA2、TA10:

- Chemical Equipment – Heat exchangers, pressure vessels.

- Marine Engineering – Hull components, propeller shafts.

- Medical Devices – Orthopedic implants.

- TC4:

- Aerospace – Aircraft frames, engine components.

- Energy Industry – Nuclear power plant components.

- High-performance Sports Equipment – Racing car components.

Summary

Our titanium plates, bars, processed parts, and forgings deliver outstanding performance across diverse industries. Backed by customization capabilities and strict quality standards, we provide reliable material solutions tailored to your specific needs.

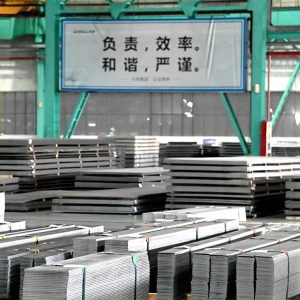

Warehouses

Workability

HK Hantie’s laminated metal products are versatile in processing, offering capabilities such as deep drawing, steel sheet punching, V-bending, 180° bending, printing, CNC engraving, and custom requests.

We also provide cutting services for film-coated glass to meet customer needs.

Packing & Delivery

Export packaging or customized packaging as per customer requirements, with reinforced protection during shipment to ensure product stability.

FAQ

Relative Products

Steel Plates Medium and heavy plates refer to steel plates with a thickness generally ranging from 4mm to 100mm. They are

Stainless Steels We supply a full range of stainless steel products, including austenitic stainless steel, ferritic stainless steel, martensitic stainless steel,

Cold Rolled Steel Coils Cold Rolled Steel Coils Full Range of Cold-Rolled Steel ProductsWe supply a full range of cold-rolled steel

Contact