Galvanized Steel (GI)

We supply a full range of galvanized steel products, including hot-dip galvanized, electro-galvanized, and alloyed galvanized steel. All products are sourced from leading steel mills.

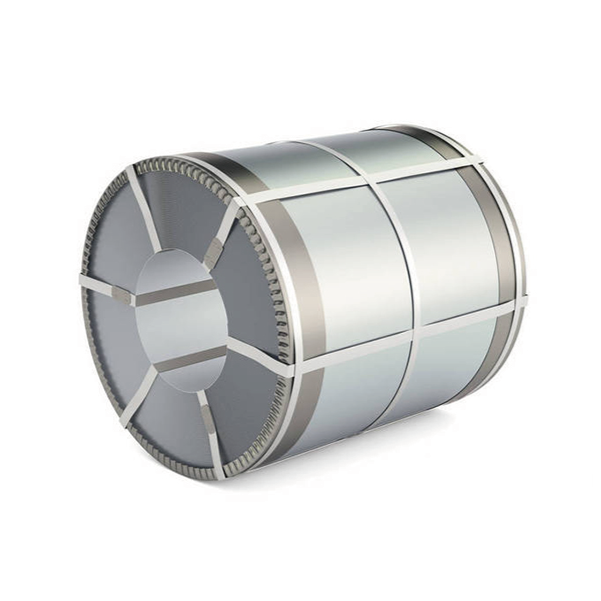

| Property | Specification |

|---|---|

| Thickness | 0.12mm – 3.0mm |

| Zinc Coating Thickness | 60 – 275 g/m² |

| Inner Coil Dia. | 508mm or 610mm |

| Width | 900 – 1500mm |

| Spangle | Regular Spangle, Large Spangle, Small Spangle, Zero Spangle |

| Surface | Bright, Oiled, Passivated, Anti-Fingerprint |

| Standards | GB, ASTM, EN, JIS etc. |

| Grades | DX51D, DX52D, DX53D, CS Type A/B/C, FS Type A/B, SGCC, SGCD1/2/3, SGCH etc. |

Introduction of Galvanized Steel (GI)

Galvanized steel coil refers to a product in which a layer of zinc is applied to the surface of a steel sheet or strip to enhance its corrosion resistance. The zinc coating provides long-lasting protection for the substrate through physical isolation and sacrificial anode action, making it widely used in construction, home appliances, and the automotive industry.

What is GI

Galvanized steel coil is a coiled steel sheet produced by applying a zinc coating to a steel strip substrate through either hot-dip galvanizing or electro-galvanizing. In the galvanizing process, the steel strip is immersed in a molten zinc bath or coated with zinc using an electroplating technique, forming a protective layer that prevents rust and corrosion.

The zinc coating not only provides effective corrosion protection but also offers good workability and an attractive appearance, making it widely used in industrial products that require long-term corrosion resistance and aesthetic appeal.

Production Process of GI

Galvanized steel coils are mainly produced through the following processes:

- Hot-dip galvanizing: The steel coil is immersed in molten zinc, allowing the zinc to adhere uniformly to the steel surface. This is the most common galvanizing method.

- Electro-galvanizing: Zinc is deposited onto the steel surface through an electrochemical reaction. This method produces a thinner but more uniform zinc coating.

- Alloyed galvanizing: After hot-dip galvanizing, the steel undergoes an annealing process, causing a reaction between zinc and iron to form a zinc-iron alloy layer. This improves high-temperature resistance and weldability.

Classification of GI

Galvanized steel coils can be classified based on production process and application:

- By production process:

- Hot-dip galvanizing

- Alloyed galvanizing

- Electro-galvanizing

- Single-sided and double-sided galvanizing

- By application:

- Structural galvanized steel sheets

- Galvanized steel sheets for home appliances

- Deep-drawing galvanized steel sheets

Standards for GI

Common standards for galvanized steel coils include:

- Chinese Standards:

- GB/T 2518: Applicable to hot-dip galvanized steel sheets and strips, specifying technical requirements, dimensions, surface quality, and inspection methods.

- American Standards:

- ASTM A653/A653M: Applicable to hot-dip galvanized steel sheets, specifying performance requirements, surface quality, and coating thickness.

- European Standards:

- EN 10346: Covers technical requirements for hot-dip galvanized steel sheets used in construction, automotive, and other industries.

- Japanese Standards:

- JIS G3302: Specifies requirements for hot-dip galvanized steel strips, including dimensions, surface quality, and inspection methods.

Applications of GI

- Construction: Roofing sheets, wall panels, floor decking, etc.

- Home Appliances: Refrigerator back panels, air conditioner casings, washing machine casings, etc.

- Automotive: Body structural components, bumper beams, etc.

- Industrial Equipment: Ventilation ducts, storage tanks, etc.

Advantages of GI

| Advantages | Disadvantages |

|---|---|

| Strong Corrosion Resistance | Low High-Temperature Resistance |

| Good Formability | Zinc Layer May Peel Off Under Strong Mechanical Stress |

| Customizable Zinc Coating Thickness and Surface |

Summary

Galvanized steel coil is a specialized steel product enhanced with a zinc coating to improve its corrosion resistance. It is widely used in the construction, home appliance, automotive, and transportation industries. The production process includes cleaning, pickling, and hot-dip or electro-galvanizing, where the thickness and quality of the coating directly impact its corrosion resistance. By adhering to relevant international and domestic standards, galvanized steel coil ensures product consistency and reliability, playing a vital role in various industrial applications.

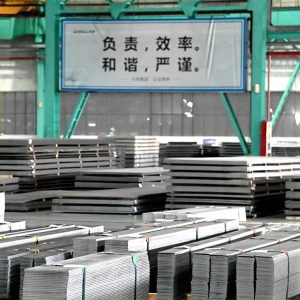

Warehouses

Workability

HK Hantie’s laminated metal products are versatile in processing, offering capabilities such as deep drawing, steel sheet punching, V-bending, 180° bending, printing, CNC engraving, and custom requests.

We also provide cutting services for film-coated glass to meet customer needs.

Packing & Delivery

Export packaging or customized packaging as per customer requirements, with reinforced protection during shipment to ensure product stability.

FAQ

Relative Products

Loading…

Loading…

Contact