PCM Pre-painted metal sheet

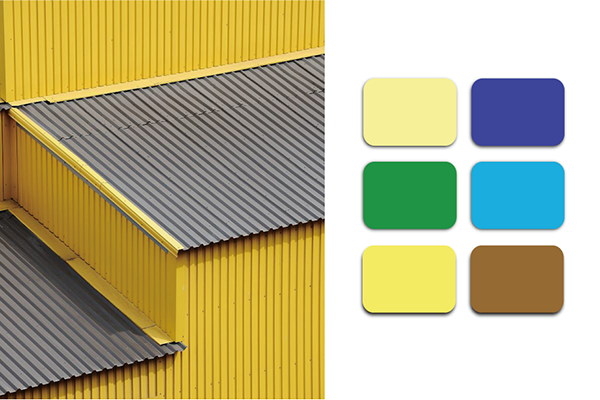

Pre-painted Metal Sheets (PCM) are composite materials primarily manufactured by applying one or more layers of coatings onto metal coils through a roller-coating process, followed by high-temperature baking. This method produces metal sheets or coils with decorative effects such as solid colors, pearlescent finishes, and patterns. PCM products offer advantages like vibrant colors, high production efficiency, quick turnaround, and environmental friendliness. When PCM is applied over galvanized substrates, it is referred to as Pre-painted Galvanized Iron (PPGI).

PCM Steel Sheets Presentation

Advantages

- Workability: Exceptional formability, including deep drawing and bending, tailored to customer requirements and the type of metal substrate.

- Consistency: Achieves precise and uniform coloration through multiple coating and baking processes.

- Corrosion Resistance: The coating isolates the steel sheet from direct exposure to the external environment, enhancing its resistance to corrosion.

- Eco-friendliness: Surface coatings comply with environmental standards such as RoHS, LFGB, REACH, and PAHS.

Product Details

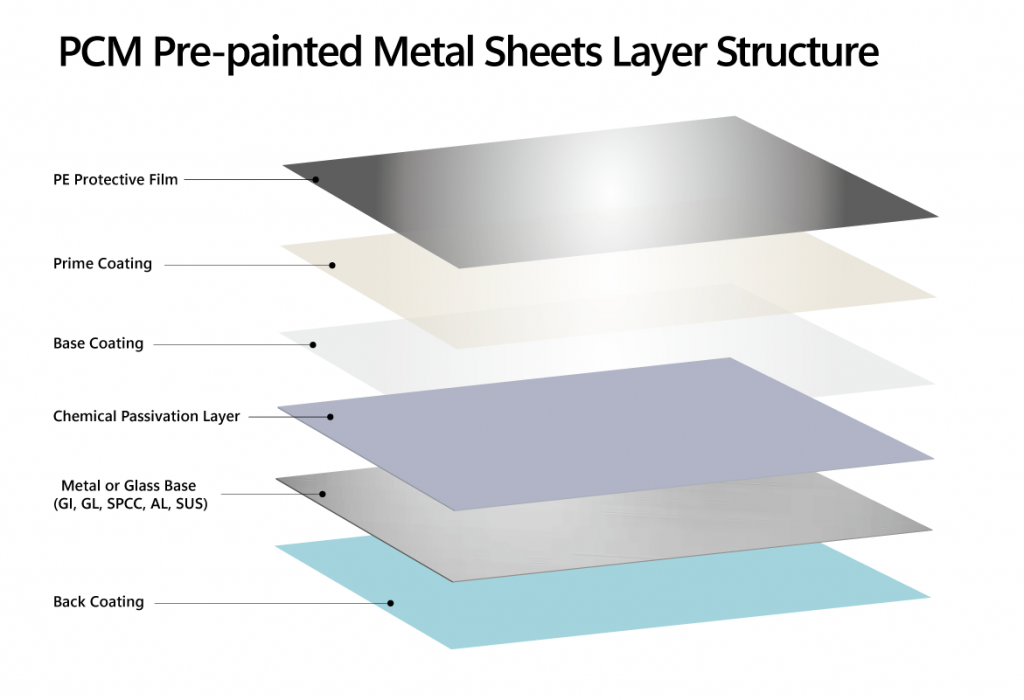

Product Structure:

Below is the detailed layers of Pre-painted Metal Sheets (PCM).

PCM Specifications and Ordering Conditions

| ITEMS | Details |

|---|---|

| Base Material | Cold-rolled steel sheets, hot-dip galvanized steel sheets, electro-galvanized steel sheets, stainless steel sheets, aluminum sheets, etc. |

| Grades | SGCC, SPCC, DX51D, DX52D, DX53D, DX54D |

| Base Material Thickness | Steel sheets: 0.2-1.5mm, Aluminum sheets: 0.3-2.5mm |

| Dimensions | Width: ≤1250mm, Length: ≤5000m, customizable upon request |

| Total Thickness | Base material thickness + (0.02-0.05mm), customizable upon request |

| Available Coils | Width: ≤1250mm, Single coil weight: ≤5500KG, Steel coil inner diameter: ≤510mm |

| Minimum Order Quantity | Min. 20 metric tons |

| Production Cycle | Approximately 30 days |

| Payment Terms | T/T, L/C, Western Union |

Workability

HK Hantie’s laminated metal products are versatile in processing, offering capabilities such as deep drawing, steel sheet punching, V-bending, 180° bending, printing, CNC engraving, and custom requests.

We also provide cutting services for film-coated glass to meet customer needs.

APPLICATIONS

- Appliance Enclosures

Refrigerators, freezers, washing machines, air conditioners, microwave ovens, water heaters, ovens, televisions, DVD players, lighting fixtures, and more. - Outdoor Decorations

Roofing, interior and exterior wall decorations, and steel structures. - Office Supplies

Various office-related applications.

Relative Products

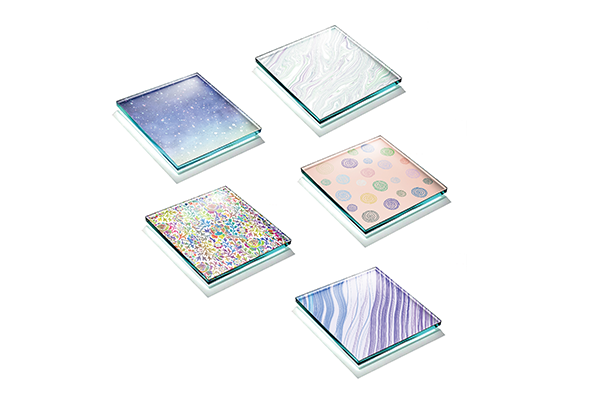

Film Coated Glass Film Coated Glass is a colored glass material made by laminating a polymer film onto the back of

Anti-fingerprint Stainless Steels Anti-fingerprint Stainless Steel is a type of stainless steel that features an eco-friendly nano coating on its surface,

PCM Pre-painted metal sheet Pre-painted Metal Sheets (PCM) are composite materials primarily manufactured by applying one or more layers of coatings

Contact