Zr Ti Steel Clad Plate

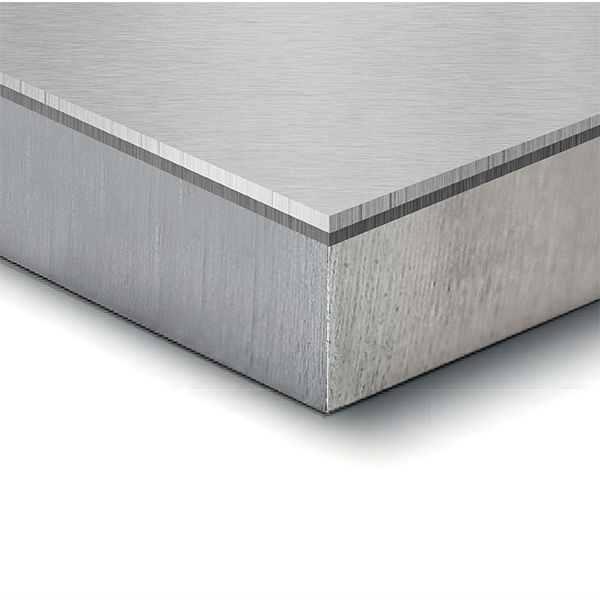

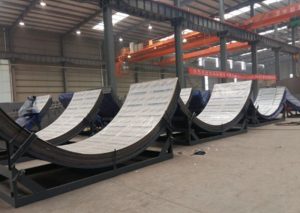

The zirconium/titanium/steel clad plate is a multi-layer composite material typically made by bonding zirconium, titanium, and carbon steel or stainless steel through explosive welding. Zirconium, known for its exceptional corrosion resistance and good machinability, is well-suited for applications such as pressure vessel shells, heat exchanger tube sheets, tower components, and piping. However, using pure zirconium for pressure vessels is expensive and inefficient, often resulting in resource waste. Therefore, it is commonly combined with steel to optimize both cost and material usage.

Direct bonding of zirconium and steel can lead to brittle intermetallic compounds that weaken the bond, so an intermediate layer is used to improve strength. A commercially pure titanium sheet (usually 2-3 mm thick) serves as this transition layer, creating a three-layer clad plate: zirconium-titanium-steel. This clad plate combines the corrosion resistance (resistant to strong acids and alkalis) and radiation tolerance of zirconium with the strength and cost advantages of the steel base, making it ideal for use in the chemical industry, nuclear sector, marine engineering, and medical fields where high corrosion resistance and strength are critical.

PRODUCING CONDITION

ASTM B898 ,GB/T 4746, EN 13445 ect.

Carbon steels such as ASME SA516, ASTM A516 Gr. 55, 60, 65, 70; Stainless steels like: ASTM A240, ASME SA240, ASTM A789, ASME SA789, ASTM A182, ASME SA182, EN 10028-2, EN 10088-2, EN 10088-7 etc.

ASTM B551; ASME SB551; GB/T 8769;ASTM B265;ASME SB-265;GB/T 3621 ect.

| Clad Layer THX. | TTL THX. | Max. Width | Max. Length | |

|---|---|---|---|---|

| Explosive | min. 2mm | – | 4.5m | 14m |

| Explosive + Rolling | 0.8-2mm | max. 152mm | 4.5m | 14m |

| Rolling | 0.8-14mm | 8-40mm | 4.5m | 14m |

characteristics

Different composite methods have varying requirements for the cladding and base materials. We can provide customized production based on the specific needs of our customers.

Chemical Composition

Zirconium Clad layer chemical analysis (wt%) as below:

| C | O | Zr | Hf | Fe+Cr | H | N |

|---|---|---|---|---|---|---|

| 0.05 | 0.16 | Bal. | 4.5 | 0.2 | 0.005 | 0.025 |

Chemical Composition

Titanium Clad layer chemical analysis (wt%) as below:

| C | N | Ti | Fe | H | O | Others |

|---|---|---|---|---|---|---|

| 0.1 | 0.05 | Bal. | 0.3 | 0.015 | 0.25 | 0.5 |

Third Party Certificate

In accordance with ASTM A578/A578M Level B, we perform 100% ultrasonic testing (UT), ensuring a bonding rate of over 99%. Tests for chemical composition, mechanical properties, low-temperature impact, hardness, PWHT (Post Weld Heat Treatment), and HIC (Hydrogen-Induced Cracking) can be conducted as per customer requirements.

Additionally, we provide EN 10204 – 3.2 certification.

CERTIFICATION

The company has achieved ISO 9001 Quality Management System certification, ISO 14001 Environmental Management System certification, and Occupational Health and Safety Management System certification. Other certifications, such as PED and API, are currently in the application process. Our clad plate products have also received CE certification for pressure vessels, while our marine clad plates have been certified by six national classification societies, including CCS, DNV GL, LR, BV, RINA, and ABS.

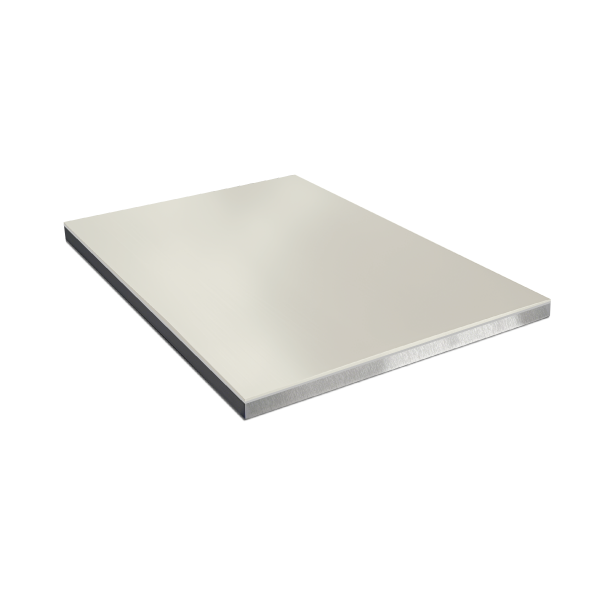

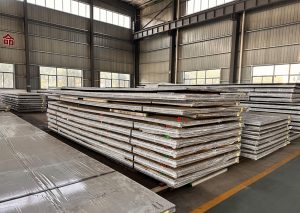

DELIVERY AND PACKING

Below is our standard packing method for export transportation, for other special requirements from our customers, we can customize. The surface of the clad plates is covered with a PE plastic film, followed by a layer of hard cardboard for protection. The outermost layer is waterproofed, and labels are applied to ensure effective identification. The product is then loaded for shipment.

FAQ

Relative Products

Loading…

Relative Products

Contact