Ta Zr Ti Steel Clad Plate

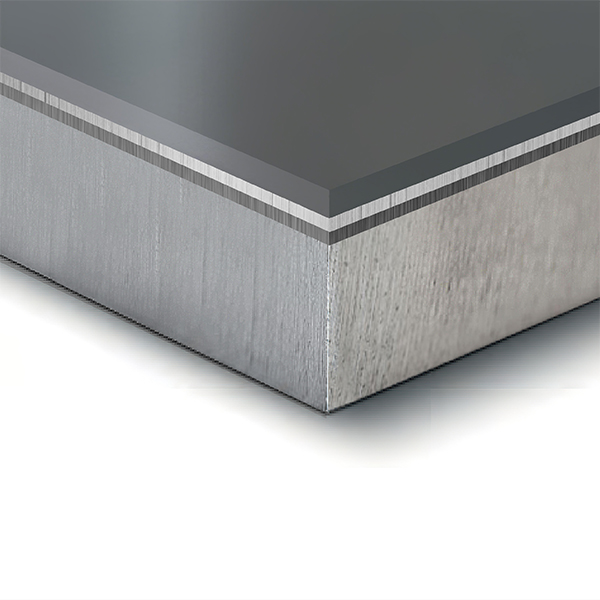

The Tantalum/Zirconium/Titanium/Steel clad plate is indeed an exceptional multilayer material. Its sophisticated design provides high corrosion resistance and mechanical strength. The plate is manufactured using explosive welding, a process that uses explosive energy to bond different metal layers tightly together, allowing each layer to contribute its unique advantages.

The specific process steps are as follows: First, explosive welding is used to bond zirconium, titanium, and the steel base into a single unit. Titanium and zirconium have excellent bonding characteristics, achieving a stable interface through explosive welding. Then, the zirconium/titanium/steel composite plate is subjected to a second explosive bonding process with tantalum, making tantalum the outermost layer, which provides maximum corrosion protection.

This multilayer structure takes advantage of the properties of different metals, with tantalum as the corrosion-resistant layer, significantly enhancing the stability of the composite material’s performance. It is particularly suitable for equipment used in highly corrosive environments, such as those found in the chemical, petroleum, and pharmaceutical industries. Since tantalum is rare and expensive, this multilayer design substantially reduces the amount of tantalum required, effectively controlling material costs while ensuring the equipment’s durability and long-term stability.

PRODUCING CONDITION

ASTM B898 ,GB/T 23447 ect.

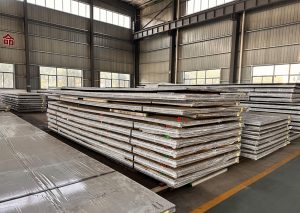

Carbon steels such as ASME SA516, ASTM A516 Gr. 55, 60, 65, 70; Stainless steels like: ASTM A240, ASME SA240, ASTM A789, ASME SA789, ASTM A182, ASME SA182, EN 10028-2, EN 10088-2, EN 10088-7 etc.

ASTM B551; ASME SB551; GB/T 8769;ASTM B265;ASME SB-265;GB/T 3621;ASTM B708 etc.

| Clad Layer THX. | TTL THX. | Max. Width | Max. Length | |

|---|---|---|---|---|

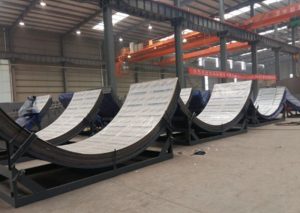

| Explosive | min. 2mm | – | 4.5m | 14m |

| Explosive + Rolling | 0.8-2mm | max. 152mm | 4.5m | 14m |

| Rolling | 0.8-14mm | 8-40mm | 4.5m | 14m |

characteristics

Different composite methods have varying requirements for the cladding and base materials. We can provide customized production based on the specific needs of our customers.

Mechanical Performance

Mechanical performance as below:

| A.A | DIM | SQ | CTM | BR(%) | T.S Rm/(Mpa) | Y.S ReL/(Mpa) | E.L A/% | I.B.T d=1.5a 180° | E.B.T d=1.5a 180° | SS Ta/Zr (Mpa) | SS Zr/Ti (Mpa) | SS Ti/Steel (Mpa) | U.T |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C.P | PASS | PASS | PASS | 100% | 405 | 285 | 18.5 | PASS | PASS | 234 | 245 | 215 | PASS |

| A.A: Analysis Area DIM: Dimension SQ: Surface Quality CTM: Cladding Thickness Measurement | BR(%): Bonding Rate T.S Rm/(Mpa): Tensile Strength Y.S ReL/(Mpa): Yield Strength E.L A/%: Percentage Elongation After Fracture | S.S. τ/MPa: Shear Strength U.T: Ultrasonic Testing I.B.T d=1.5a 180°: Backside Bending angle=180° E.B.T d=1.5a 180°: Frontside Bending angle=180° |

|||||||||||

Third Party Certificate

In accordance with ASTM A578/A578M Level B, we perform 100% ultrasonic testing (UT), ensuring a bonding rate of over 99%. Tests for chemical composition, mechanical properties, low-temperature impact, hardness, PWHT (Post Weld Heat Treatment), and HIC (Hydrogen-Induced Cracking) can be conducted as per customer requirements.

Additionally, we provide EN 10204 – 3.2 certification.

CERTIFICATION

The company has achieved ISO 9001 Quality Management System certification, ISO 14001 Environmental Management System certification, and Occupational Health and Safety Management System certification. Other certifications, such as PED and API, are currently in the application process. Our clad plate products have also received CE certification for pressure vessels, while our marine clad plates have been certified by six national classification societies, including CCS, DNV GL, LR, BV, RINA, and ABS.

DELIVERY AND PACKING

Below is our standard packing method for export transportation, for other special requirements from our customers, we can customize. The surface of the clad plates is covered with a PE plastic film, followed by a layer of hard cardboard for protection. The outermost layer is waterproofed, and labels are applied to ensure effective identification. The product is then loaded for shipment.

FAQ

Relative Products

Loading…

Relative Products

Contact