Nickel Base Alloy Clad Plates

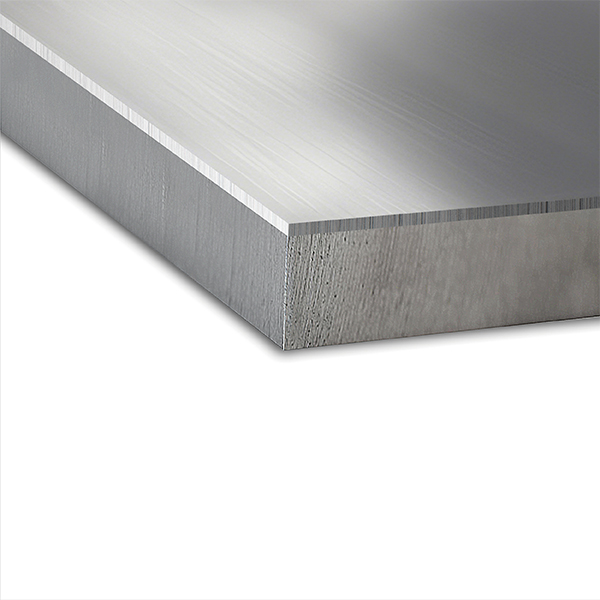

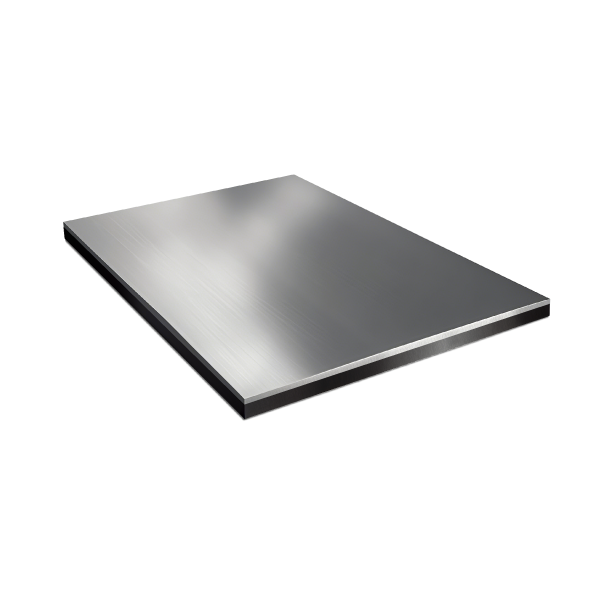

Nickel base alloy clad plates are cladded materials made by bonding nickel-based alloys with carbon steel or stainless steel substrates through composite processes. They combine the excellent corrosion resistance of nickel-based alloys with the mechanical strength and cost advantages of the substrate.

Nickel based alloys are known for their outstanding resistance to corrosion and oxidation in extreme environments such as high temperatures, strong acids, and alkalis, making them ideal for use in industries like chemical processing, marine engineering, and nuclear power. Through composite processes like explosion welding and hot rolling, nickel-based alloy composite plates merge the surface properties of nickel-based alloys with the strength and toughness of the substrate, reducing costs while enhancing the overall material performance.

These materials are particularly suitable for demanding environments that require high-temperature and corrosion resistance, such as petrochemical equipment, seawater desalination plants, and pressure vessels.

PRODUCING CONDITION

ASTM A265,ASTM A264,JIS G 3602,NB/T 47002 ect.

Carbon steels such as ASME SA516, ASTM A516 Gr. 55, 60, 65, 70; Stainless steels like: ASTM A240, ASME SA240, ASTM A789, ASME SA789, ASTM A182, ASME SA182, EN 10028-2, EN 10088-2, EN 10088-7 etc.

ASTM B168 N06600;ASTM B409 N 08800,N08801;ASTM B421 N04400;ASTM B424 N08825;ASTM B443 N06625;ASTM B575 N10276 (alloy C276) etc

| Clad Layer THX. | TTL THX. | Max. Width | Max. Length | |

|---|---|---|---|---|

| Explosive | min. 3mm | – | 4.5m | 14m |

| Rolling | 0.8-15mm | 3-300mm | 4.5m | 14m |

characteristics

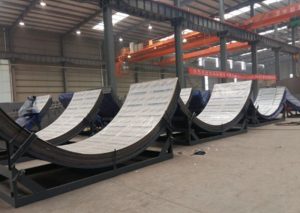

Different composite methods have varying requirements for the cladding and base materials. We can provide customized production based on the specific needs of our customers.

Third Party Certificate

In accordance with ASTM A578/A578M Level B, we perform 100% ultrasonic testing (UT), ensuring a bonding rate of over 99%. Tests for chemical composition, mechanical properties, low-temperature impact, hardness, PWHT (Post Weld Heat Treatment), and HIC (Hydrogen-Induced Cracking) can be conducted as per customer requirements.

Additionally, we provide EN 10204 – 3.2 certification.

CERTIFICATION

The company has achieved ISO 9001 Quality Management System certification, ISO 14001 Environmental Management System certification, and Occupational Health and Safety Management System certification. Other certifications, such as PED and API, are currently in the application process. Our clad plate products have also received CE certification for pressure vessels, while our marine clad plates have been certified by six national classification societies, including CCS, DNV GL, LR, BV, RINA, and ABS.

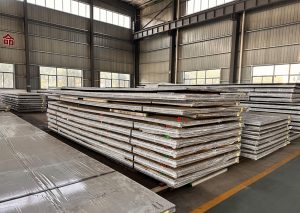

DELIVERY AND PACKING

Below is our standard packing method for export transportation, for other special requirements from our customers, we can customize. The surface of the clad plates is covered with a PE plastic film, followed by a layer of hard cardboard for protection. The outermost layer is waterproofed, and labels are applied to ensure effective identification. The product is then loaded for shipment.

FAQ

Relative Products

Loading…

Relative Products

Contact