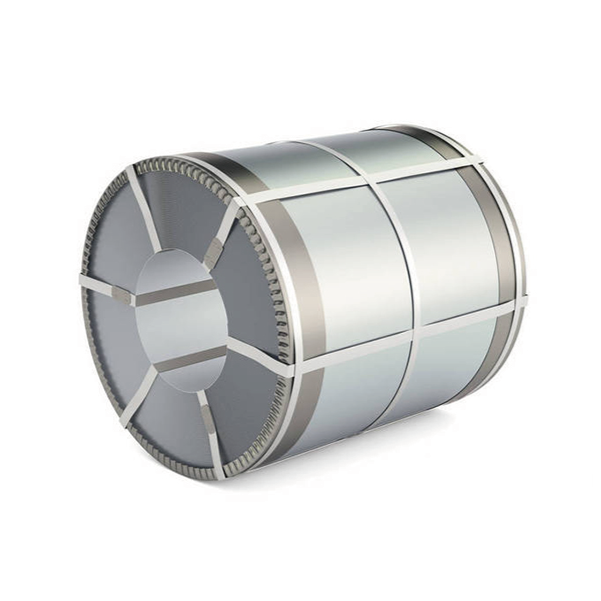

Aluminum-Zinc Coated Steel (GL)

We supply a full range of Aluzinc steel products, including Aluzinc for construction and home appliances. All products are sourced from well known steel mills.

| Property | Specification |

|---|---|

| Thickness | 0.12mm – 3.0mm |

| Aluminum-Zinc Coating Thickness | 50 – 150 g/m² |

| Inner Coil Dia. | 508mm or 610mm |

| Width | 900 – 1500mm |

| Zinc Spangle | Regular Spangle, Large Spangle, Small Spangle, Zero Spangle |

| Surface | Bright, Oiled, Passivated, Anti-Fingerprint |

| Standard | GB, ASTM, EN, JIS etc. |

| Grades | DX51D+AZ, DX52D+AZ, CS Type A/B, FS, SS Grade 33/37/50/80, SGLCC, SGLCD1/2/3 etc. |

Introduction

Aluzinc coils are steel products with an aluminum-zinc alloy coating on the surface. This product combines the excellent properties of aluminum and zinc, offering enhanced corrosion resistance, thermal stability, and high oxidation resistance. As a result, it is widely used in industries requiring high corrosion resistance and aesthetic quality. Aluzinc coils are particularly suitable for construction, home appliances, and automotive applications, demonstrating superior corrosion resistance, especially in high-temperature or humid environments.

What Are Aluzinc Coils

Aluzinc coils are steel products coated with an aluminum-zinc alloy to enhance corrosion resistance, high-temperature performance, and oxidation resistance. The aluminum-zinc alloy typically contains approximately 55% aluminum, 43.4% zinc, and a small amount of silicon. This alloy layer provides dual protection: the aluminum layer effectively resists high-temperature oxidation, while the zinc layer prevents corrosion.

Compared to traditional galvanized steel, aluzinc steel offers superior resistance to high temperatures, oxidation, and corrosion, making it more suitable for applications exposed to extreme environments over extended periods.

Production Process of Aluzinc Coils

The production of aluzinc coils involves a hot-dip coating process, where the steel sheet is immersed in a molten aluminum-zinc alloy to form a protective coating. The key steps include:

- Substrate Preparation: Cleaning, pickling, and annealing to ensure a clean and smooth surface.

- Coating Deposition: Applying the aluminum-zinc alloy layer onto the steel sheet through the hot-dip process.

- Post-Treatment: Processes such as passivation, oiling, or anti-fingerprint coating to enhance corrosion resistance, workability, and other specific properties.

Classification of Aluzinc Steels

Aluzinc sheets are primarily classified based on their application, including: Construction Aluzinc Sheets, Home Appliance Aluzinc Sheets.

Standards for Aluzinc Steels

- Chinese Standard:

- GB/T 2518 – Covers requirements for hot-dip Aluzinc steel sheets and coils, including coating thickness, mechanical properties, and corrosion resistance.

- American Standard:

- ASTM A792/A792M – Specifies the requirements for hot-dip Aluzinc steel sheets, including chemical composition, mechanical properties, and coating thickness.

- European Standard:

- EN 10346 – Defines production requirements for hot-dip Aluzinc steel sheets, covering coating thickness and mechanical properties.

- Japanese Standard:

- JIS G 3321 – Japanese standard for hot-dip Aluzinc steel coils, addressing coating thickness, surface quality, and inspection methods.

Applications of Aluzinc Steels

- Construction: Roofing, walls, canopies, etc.

- Home Appliances: Water heaters, air conditioner casings, etc.

- Energy: Solar panel substrates, power plant pipelines, etc.

- Industrial Equipment: Chemical storage tanks, chimneys, etc.

Advantages of Aluzinc Steels

| Advantages | Disadvantages |

|---|---|

| Higher corrosion resistance compared to galvanized steel coils | Slightly lower paint adhesion, requiring additional treatment |

| More suitable for energy-efficient buildings | |

| Better high-temperature resistance |

Summary

Aluminum-zinc coated steel is a specialized steel product that combines the benefits of aluminum and zinc. By applying an aluminum-zinc alloy coating on the steel surface, it offers excellent corrosion resistance, heat resistance, and oxidation resistance. Its superior performance in high-temperature and harsh environments makes it an ideal anti-corrosion material for various industries.

Warehouses

Workability

HK Hantie’s laminated metal products are versatile in processing, offering capabilities such as deep drawing, steel sheet punching, V-bending, 180° bending, printing, CNC engraving, and custom requests.

We also provide cutting services for film-coated glass to meet customer needs.

Packing & Delivery

Export packaging or customized packaging as per customer requirements, with reinforced protection during shipment to ensure product stability.

FAQ

Relative Products

Loading…

Loading…

Contact