Cold Rolled Steel Coils Cold Rolled Steel Coils

Full Range of Cold-Rolled Steel Products

We supply a full range of cold-rolled steel products, including coils, sheets, automotive steel, and electrical steel, all sourced from leading steel mills.

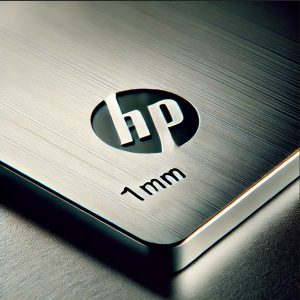

| Thickness | 0.16mm – 5mm |

|---|---|

| Inner Coil Dia. | 508mm or 610mm |

| Width | 750 – 1300mm |

| Surface | Bright Surface / Non-Oiled. |

| Standards | GB, ASTM, EN, JIS etc |

| Grades | SPCC, SPCD, SPCE, DC01, DC03, DC04, S355MC, S420MC |

Introduction

Cold-Rolled Steel Coil (CRC) refers to steel strips or coils processed through a cold rolling process. Cold-rolled steel strips are rolled at room temperature to reduce thickness, resulting in superior surface quality, dimensional accuracy, and higher mechanical properties. Compared with hot-rolled steel strips, cold-rolled steel strips have significantly improved strength, hardness, and surface quality, making them widely used in the automotive, home appliance, construction, and machinery manufacturing industries.

What is CRC

Cold-Rolled Coil refers to hot-rolled steel strips further rolled at room temperature using a cold rolling mill, typically for producing thinner steel strips with high dimensional accuracy. Cold-rolled steel strips have a smooth surface, high dimensional precision, and can be further processed into various types and specifications as needed. The key characteristics of cold-rolled steel include high strength and hardness, superior surface quality, and excellent formability and ductility.

Production Process of CRC

The production of Cold-Rolled Coils mainly involves the following steps:

- Preparation of Hot-Rolled Steel Strip – Cold-rolled steel strip is typically produced from hot-rolled steel strip, which undergoes heating, rolling, and cooling to form large-size steel sheets. At this stage, the steel strip has a rough surface and low dimensional accuracy.

- Pickling and Cleaning – The hot-rolled strip is fed into a pickling tank to remove surface oxides and impurities. After cleaning, the surface becomes smoother, preparing it for the cold rolling process.

- Cold Rolling – The cleaned strip is fed into a cold rolling mill for rolling at room temperature. The cold rolling process reduces the strip thickness under continuous pressure, significantly increasing its strength and hardness while improving surface finish.

- Annealing – Cold-rolled strips typically require annealing to eliminate internal stress caused by cold rolling, enhancing ductility and formability. The annealing process involves heating the strip to a specified temperature and then slowly cooling it.

- Coating Treatment – Based on customer requirements, the surface of the cold-rolled strip may undergo coating treatments such as galvanizing, aluminizing, or oiling to improve corrosion resistance and appearance.

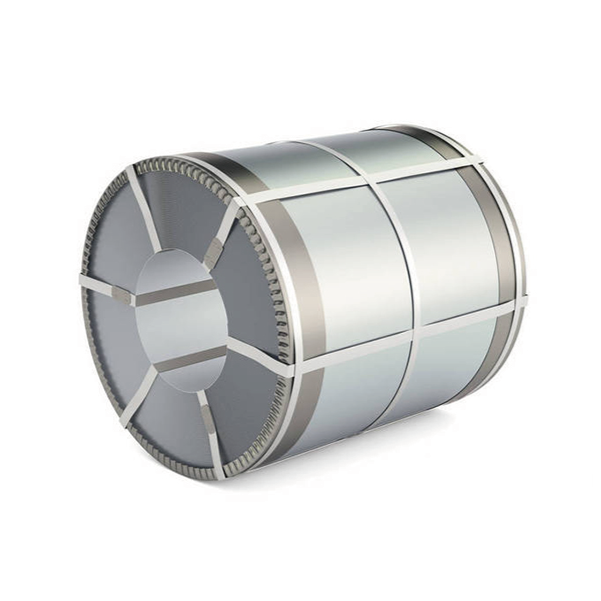

- Quality Inspection and Coiling – During production, the cold-rolled strip undergoes rigorous quality inspection to ensure dimensional accuracy, surface quality, and mechanical properties meet standards. Qualified strips are coiled, packaged, and prepared for shipment.

Classification of CRC

Cold-Rolled Steel Coils can be classified into the following categories based on production processes, applications, and surface treatments:

- General Cold-Rolled Steel Strip – Suitable for general mechanical manufacturing and structural components, commonly used in the production of cold-stamped parts and household appliance casings.

- Galvanized Cold-Rolled Steel Strip – Produced by coating the surface of cold-rolled steel strip with zinc to improve corrosion resistance. Widely used in the automotive, construction, and home appliance industries to prevent rust.

- Coated Cold-Rolled Steel Strip – Includes treatments such as oiling, plastic coating, and painting to enhance surface protection and appearance. It is widely used in household appliances, construction, and food packaging.

- High-Strength Cold-Rolled Steel Strip – This type of cold-rolled steel strip has high tensile strength and is commonly used in industries requiring high-strength materials, such as automotive and heavy machinery.

- Electrical Cold-Rolled Steel Strip – Specifically designed for motors and electrical appliances, offering low energy loss and excellent magnetic permeability.

Standards for CRC

The production and quality control of Cold-Rolled Steel Coils are regulated by various domestic and international standards. Common standards include:

- Chinese Standards:

- GB/T 5213-2008 – Applicable to cold-rolled low-carbon steel sheets and strips for general and stamping purposes. It is widely used in automotive, home appliances, construction, light industry, and other fields requiring high precision and superior surface quality.

- American Standards:

- ASTM A1008/A1008M – Covers cold-rolled carbon steel sheets and strips, specifying requirements for chemical composition, mechanical properties, and surface quality.

- European Standards:

- EN 10130 – Defines technical requirements for cold-rolled steel strips, including chemical composition, mechanical properties, dimensional tolerances, and surface quality.

- Japanese Standards:

- JIS G 3141 – Japanese standard for cold-rolled carbon steel sheets, covering mechanical properties, dimensions, surface quality, and inspection methods.

Applications of CRC

Cold-rolled steel coils are widely used across various industries due to their excellent surface quality, high dimensional accuracy, and superior mechanical properties. Key applications include:

- Automotive Industry – Cold-rolled steel coils are extensively used for manufacturing automotive body parts, including engine hoods and doors. The material’s good formability and high tensile strength make it ideal for such applications.

- Home Appliance Industry – Commonly used for the production of appliance casings, such as refrigerators, washing machines, and air conditioners. High surface smoothness and corrosion resistance are critical requirements.

- Construction Industry – Used for producing building structures, window and door frames, where high tensile strength and good formability are essential.

- Machinery Manufacturing Industry – Used for making various mechanical components and precision instrument casings. High surface finish and good weldability are key attributes.

- Packaging Industry – Used for producing easy-open cans and food containers, where good plasticity and corrosion resistance are important.

- Electronics and Electrical Industry – Utilized for manufacturing electronic equipment casings and electrical components, requiring good electromagnetic properties and surface finish.

Advantages of CRC

| Advantages | Disadvantages |

|---|---|

| Excellent surface quality and high dimensional accuracy | Poor corrosion resistance |

| Good mechanical and forming properties | Relatively low toughness |

| Relatively low cost | Limited thickness range |

Summary

Cold-rolled steel coils are processed through cold rolling at room temperature, resulting in high strength, hardness, and surface quality. They are widely used in the automotive, home appliance, construction, and machinery manufacturing industries. The production process includes steps such as pickling, cold rolling, annealing, and coating. Common product types include general-purpose cold-rolled steel coils, galvanized cold-rolled steel coils, and coated cold-rolled steel coils. The production and quality control of cold-rolled steel coils follow various domestic and international standards to meet the technical and application requirements of different industries.

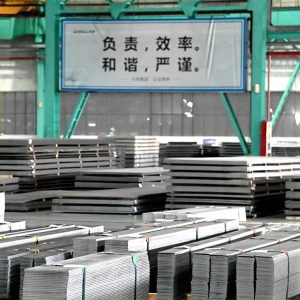

Warehouses

Workability

HK Hantie’s laminated metal products are versatile in processing, offering capabilities such as deep drawing, steel sheet punching, V-bending, 180° bending, printing, CNC engraving, and custom requests.

We also provide cutting services for film-coated glass to meet customer needs.

Packing & Delivery

Export packaging or customized packaging as per customer requirements, with reinforced protection during shipment to ensure product stability.

FAQ

Relative Products

Loading…

Loading…

Contact